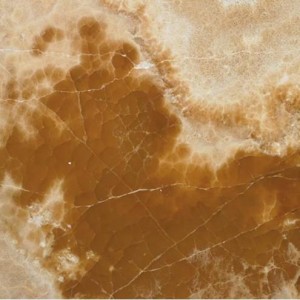

Onyx is one of the softer and more fragile stones in the industry and is prone to scratching. Therefore, after installation, careful maintenance of the slab is highly recommended. Due to the qualities of this stone, the slabs are book-matched, in which slab one and slab two will be cut and polished to create a mirror image of each other. These are then kept in sequence which allows for a consistent flow in pattern. During the polishing process, an epoxy resin is applied to the surface of the slabs to fill in any natural pits, cracks or fissures that may exist in the stone. This does not affect the durability, maintenance or beauty of the slab. It is possible for some of the more minute pits that are too small to effectively hold the resin, to reopen during other finishing stages. However, this will not detract from the overall quality or appearance of the stone. Finally, a mesh backing is adhered to the back of the stone to ensure safety while handling and fabricating the slab. As a natural stone product, it is recommended that this be sealed to extend its longevity.